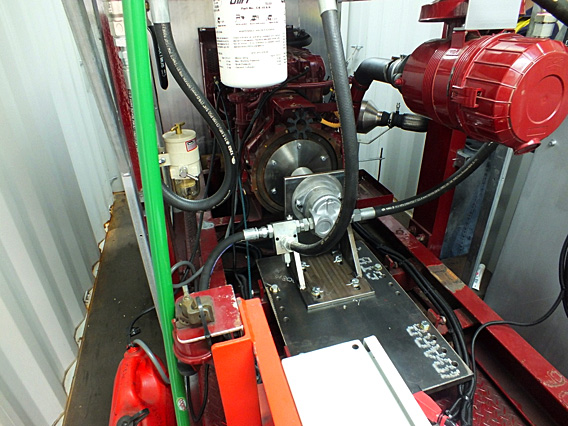

ERP Engineering Pty Ltd has developed a diesel test rig to enable various research and calibration projects to be undertaken. The test rig consists of a Detroit Diesel 706LTE engine (below).

Which has been coupled to a hydraulic pump system (below) so that varying loads can be applied to the engine thus generating varying exhaust emissions.

The system incorporates a water filled conditioning tank and a filter canister to enable the testing of disposable diesel exhaust filters commonly used in the underground mining industry.

The total system is housed in a shipping container that has been modified to attenuate the engine noise especially for long duration testing.

The system is fitted with a real time data logging system to monitor engine parameters such as exhaust back pressure, hydraulic load pressure engine rpm & hydraulic pump oil temperature.

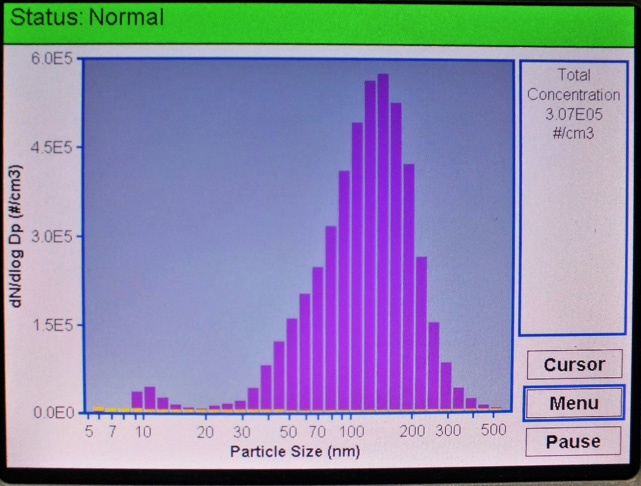

The system is also linked to a TSI Engine Exhaust Particle Sizer (EEPS) which allows the number and size of particles in the exhaust to be monitored in the 5.6 to 560 nanometre (10-9 m) range. This size range is of particular importance as it is of a size range that can enter the deep areas of the lungs. The output display of the EEPS (below) shows the size and number of diesel particulate in the exhaust in real time. This enables the evaluation of exhaust filters and respiratory protective devices.

The diesel test rig also enables the calibration of raw exhaust testing instrumentation as the engine can be loaded to varying levels which produces varying concentrations of elemental carbon (EC) in the exhaust. High volume samples can be collected at each calibration point to provide an accurate measurement of EC using NIOSH method 5040. The photograph below shows the calibration of an exhaust measurement instrument.

If you need to test your product against diesel emissions or calibrate your instrument, please contact our technical staff who will be able to advise you as to the best method achieve your objective.